Products

Cold Extruder

A Cold Extruder Machine is an industrial machine used to shape metal by forcing it through a die at room temperature. The process improves material strength, surface finish, and dimensional accuracy without heating. Cold extruders are widely used to manufacture fasteners, automotive parts, pipes, rods, and precision components, offering high production efficiency and reduced material waste.

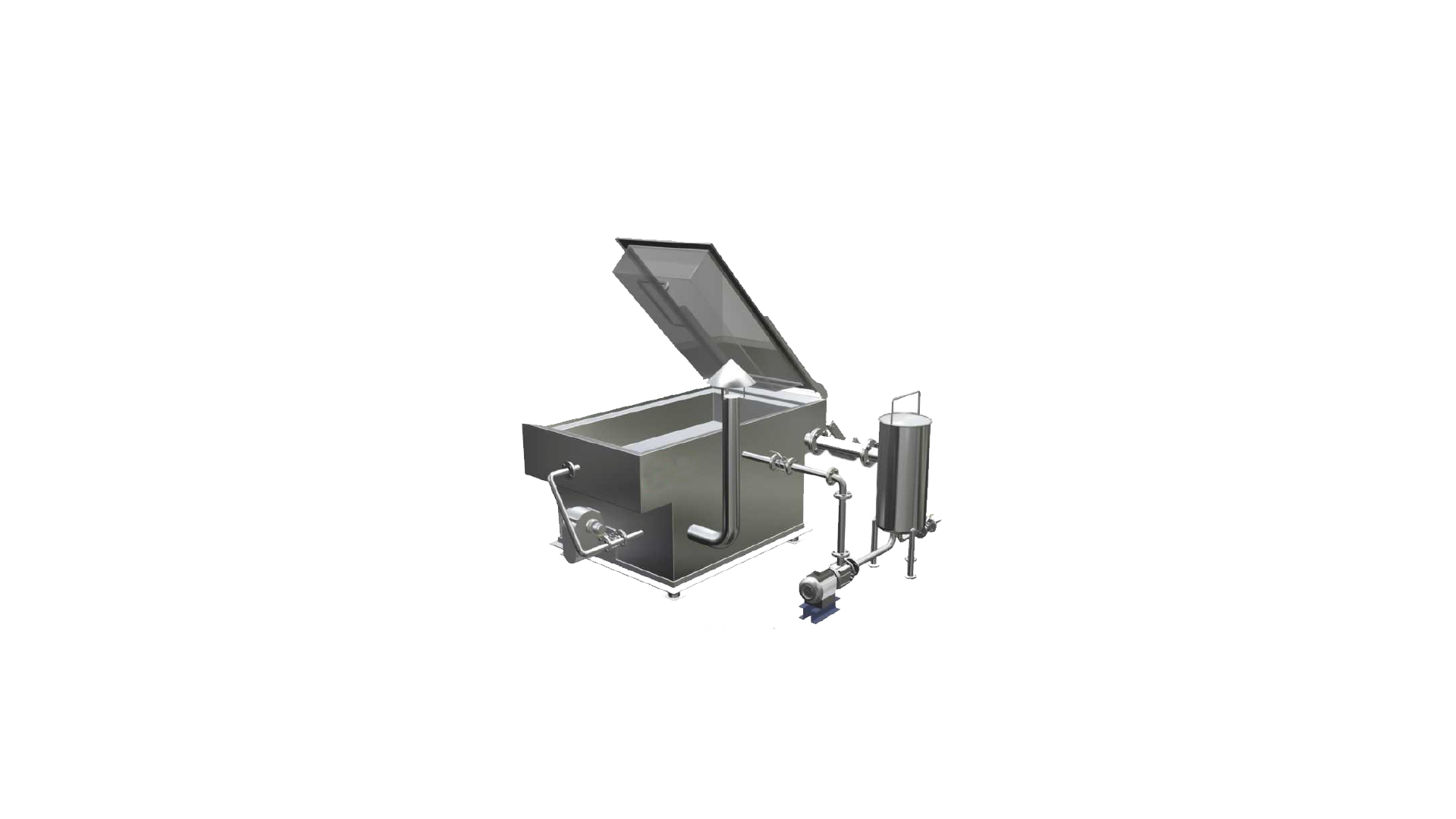

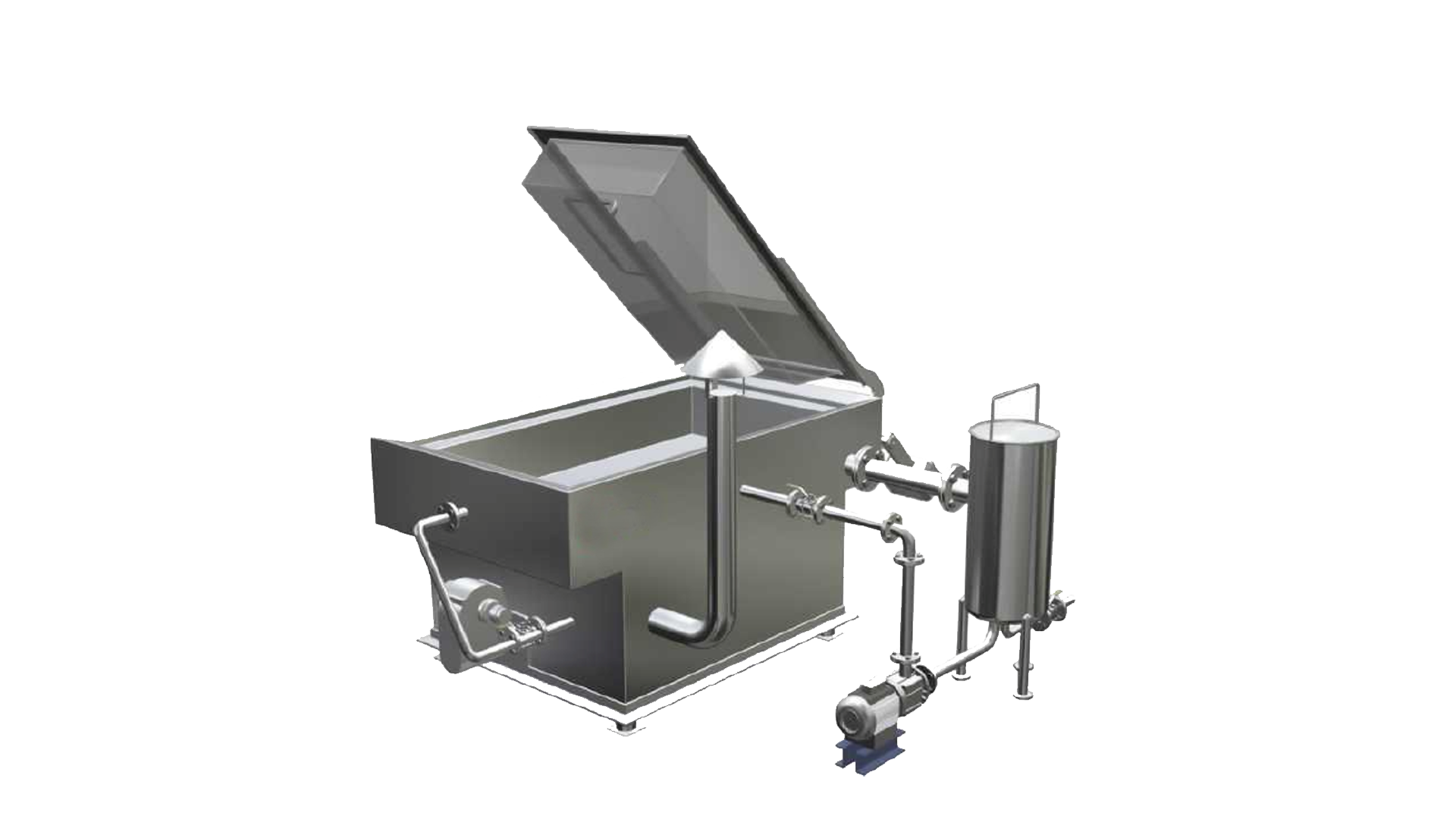

Namkeen Fryer

A Namkeen Fryer Machine is an industrial food-processing machine used for deep-frying namkeen snacks such as sev, bhujia, chips, boondi, and mixture. It ensures uniform frying, controlled oil temperature, and consistent quality, making it ideal for small to large-scale namkeen production units. The machine is typically made from food-grade stainless steel, designed for high efficiency, low oil absorption, and easy operation, helping manufacturers achieve faster production with better taste and hygiene.

Dough maker

A dough maker machine is a kitchen appliance designed to quickly and efficiently mix, knead, and prepare dough for items like roti, bread, pizza, and pastries. It saves time and effort by ensuring uniform mixing and consistent dough texture, making it ideal for both home kitchens and commercial food preparation.

Batch Mixer

The machine ensures uniform mixing of powders, granules, liquids, or semi-solid materials by rotating paddles, blades, or drums. Batch mixers are valued for their consistent output, controlled mixing time, easy operation, and flexibility to handle different formulations in small to medium production runs.

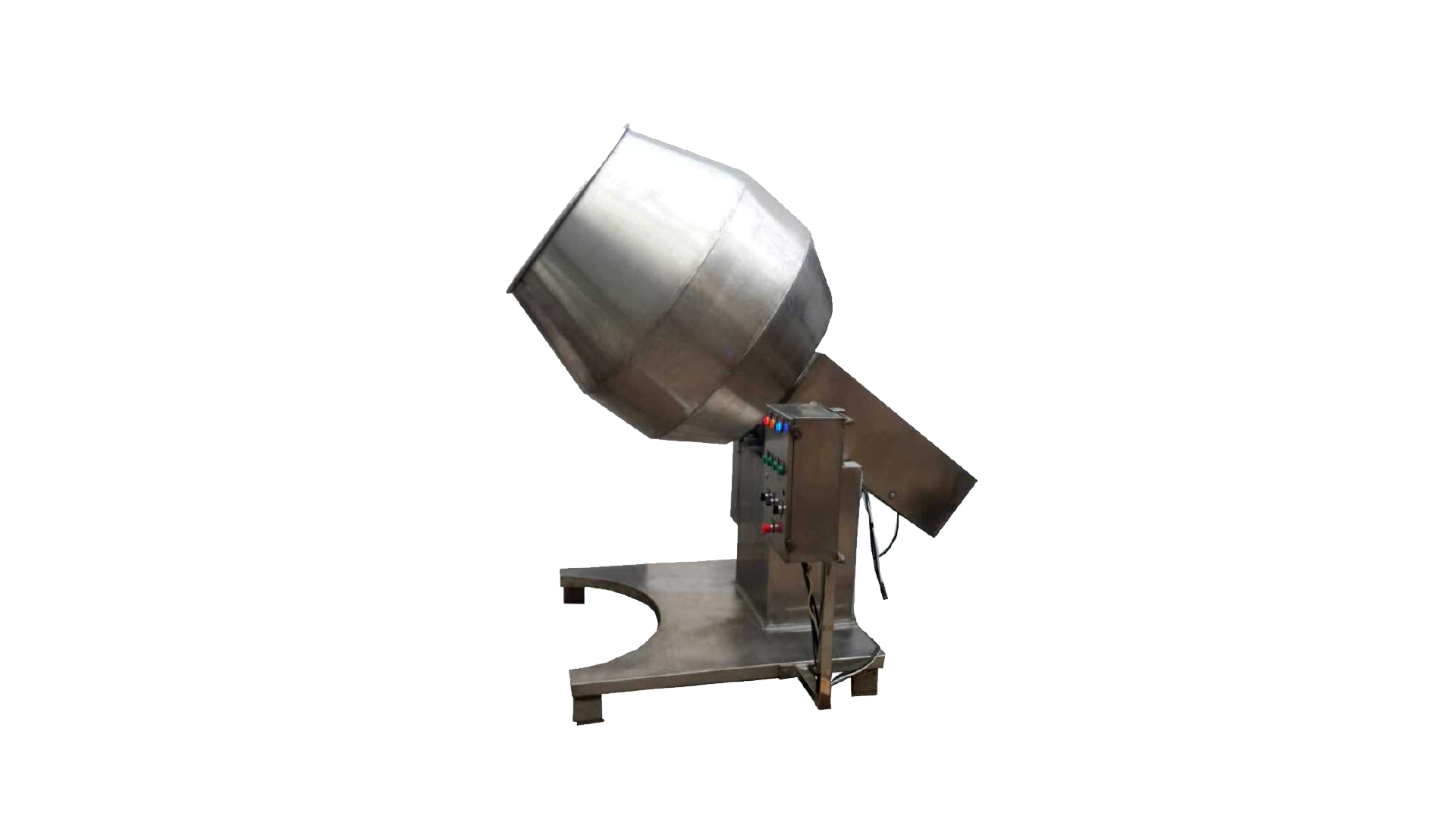

Roaster

A roaster machine is a device used to heat and roast raw materials—most commonly coffee beans, nuts, grains, or spices—to enhance their flavor, aroma, and texture. It works by applying controlled heat while continuously rotating or agitating the material to ensure even roasting and prevent burning. Roaster machines are widely used in food processing, coffee production, and commercial kitchens, and they come in various sizes ranging from small batch units to large industrial systems.

Masala Coating

A Masala Coating Machine is a food-processing machine used to evenly coat snacks and food products with spices, seasonings, or flavoring powders. It works by gently tumbling or rotating the product inside a drum while oil and masala are uniformly applied, ensuring consistent taste and appearance. These machines are widely used for coating items like namkeen, chips, peanuts, popcorn, and extruded snacks, improving efficiency, hygiene, and product quality in commercial food production.

Auger Filler Machine

An auger filler machine is a precision filling system used to accurately dispense powders, granules, and semi-powdered products into containers such as bottles, jars, pouches, or sachets. It uses a rotating auger screw driven by a servo or motor to control the exact quantity filled. These machines are widely used in food, pharmaceutical, chemical, and cosmetic industries for products like flour, spices, milk powder, protein powder, and chemicals, offering high accuracy, consistency, and automation.

Multi 10 Head Machine

A Multi-10 Head Machine is an industrial production machine designed with 10 independent working heads that operate simultaneously to perform the same task on multiple components at once. It is widely used in manufacturing and construction-related fabrication for high-volume, repetitive operations.

Collar Cup Filler Machine

A collar cup filler machine is a specialized garment-manufacturing machine used to fill and shape the collar cup area of shirts and uniforms. It ensures consistent collar stiffness, proper form, and a smooth finish by accurately inserting filler material (such as interlining or padding) into the collar. The machine improves production speed, uniform quality, and durability of collars, making it ideal for large-scale apparel manufacturing.

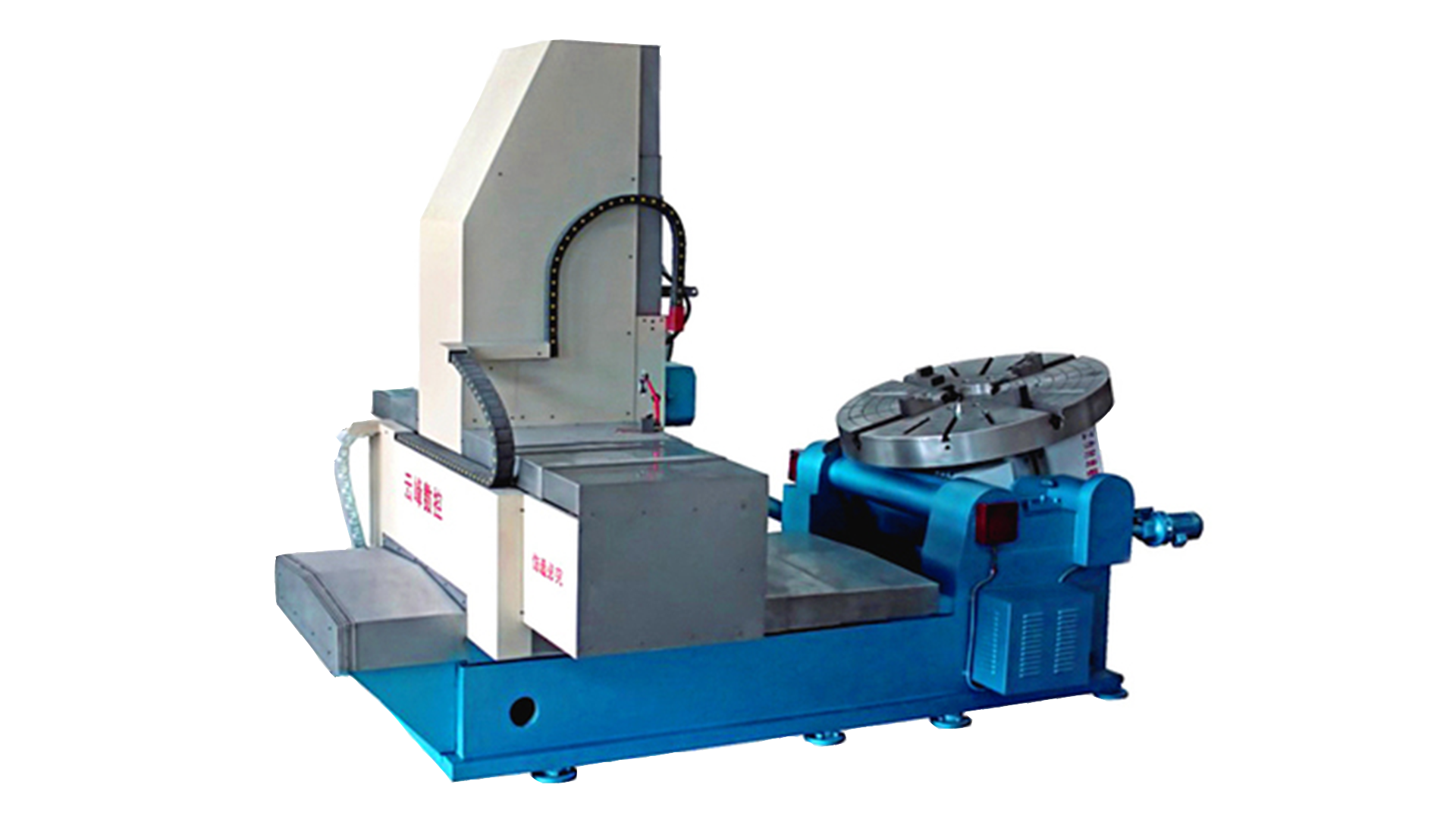

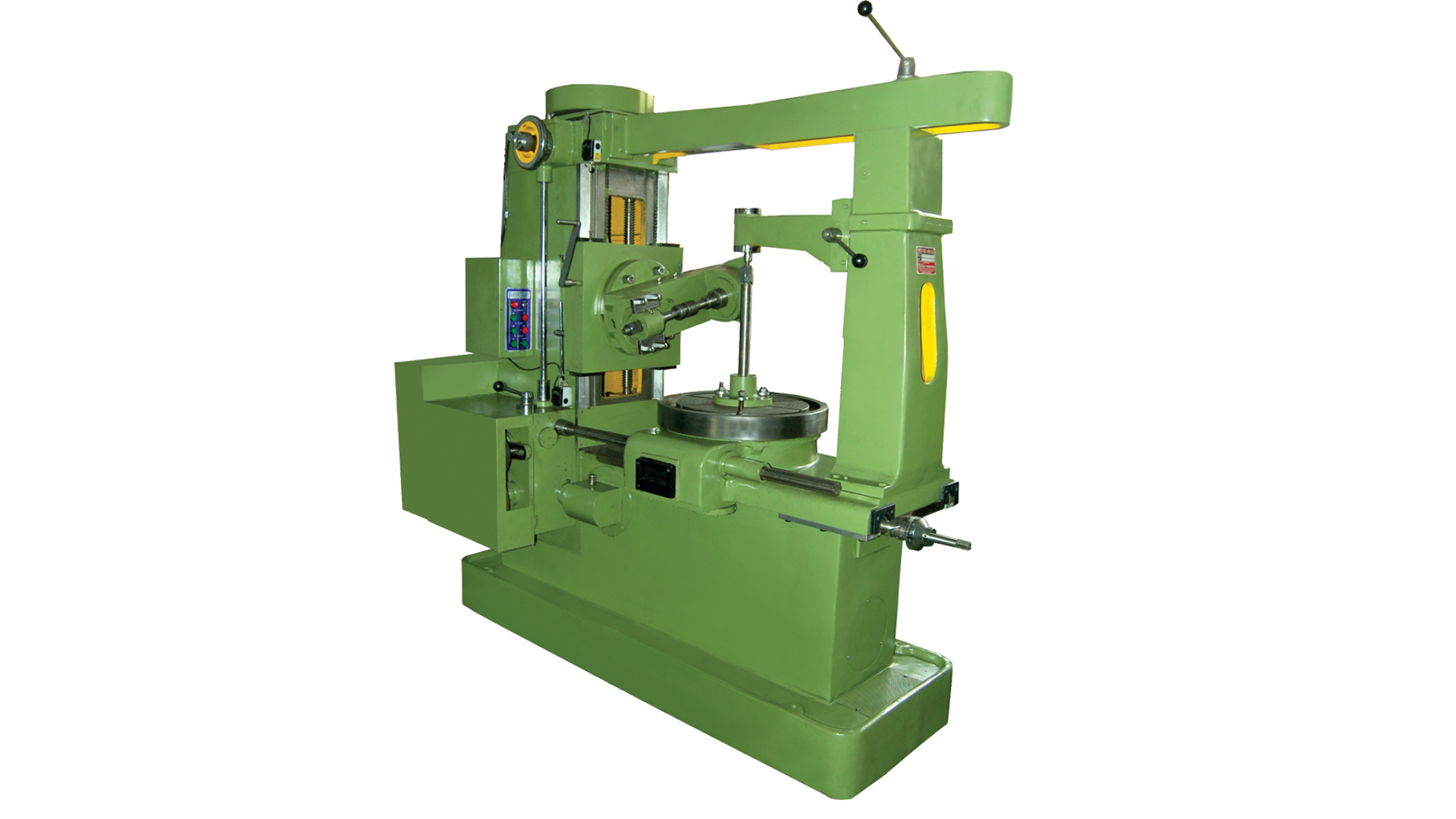

Gear Cutter

A gear cutter machine is a precision machine tool used to manufacture gears by cutting teeth into a metal blank. It shapes accurate gear profiles (such as spur, helical, bevel, or worm gears) using cutting methods like hobbing, shaping, or milling. These machines are widely used in automotive, industrial machinery, and power-transmission applications to produce durable and high-precision gears.

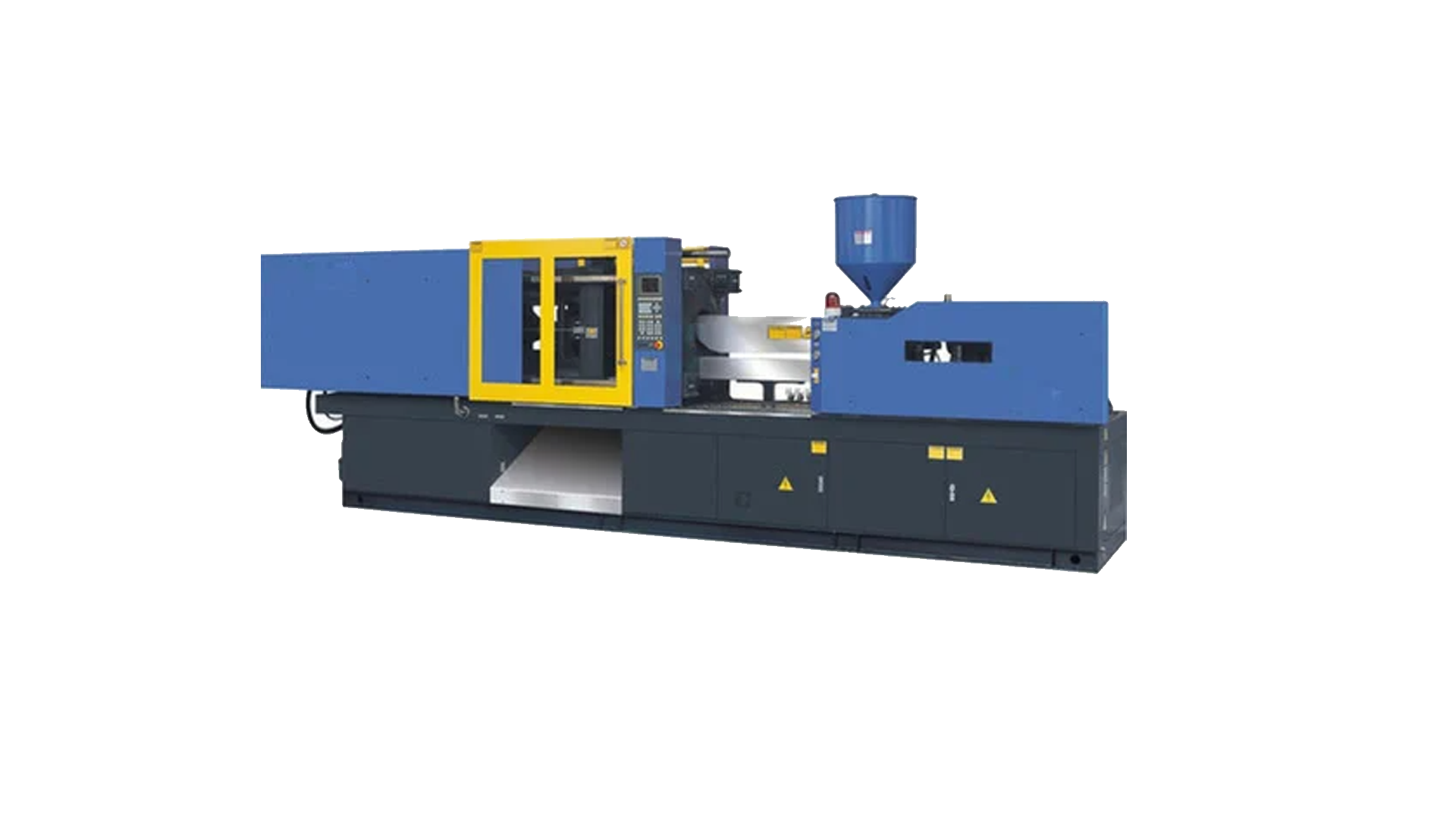

Plastic Moulding

A Plastic Moulding Machine is an industrial machine used to melt plastic raw material and shape it into finished or semi-finished products by injecting, compressing, or blowing the molten plastic into a mould. Once cooled and solidified, the mould opens to release the final product. These machines are widely used to manufacture items such as containers, automotive parts, household goods, medical components, and packaging products.

Tyre & Tube Moulding

A tyre and tube moulding machine is an industrial machine used in the rubber manufacturing process to shape, cure, and vulcanize tyres and inner tubes.

It works by placing raw rubber compounds into a mould, then applying heat and pressure so the rubber takes the exact shape, tread pattern, and strength required. The machine ensures uniform thickness, durability, and proper bonding of tyre or tube components, making it essential for producing high-quality automotive, bicycle, and industrial tyres and tubes.

In short, it converts uncured rubber into finished tyres or tubes with precise size and performance standards.